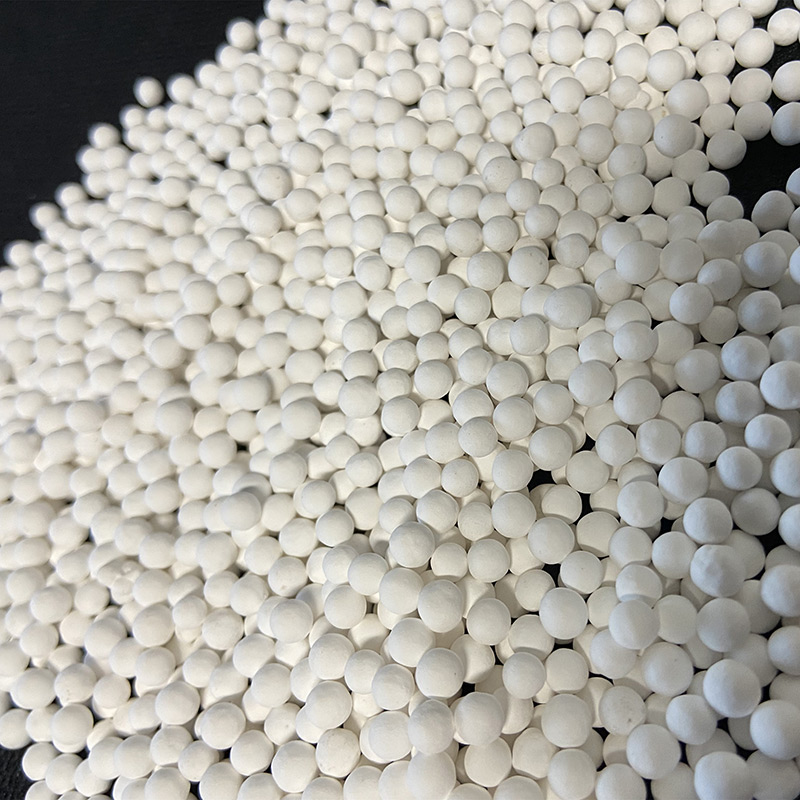

| Physical and chemical properties of inert ceramic balls | |||||||

| Element | Al2O3 % | 60 | 70 | 80 | 90 | 95 | 99 |

| Fe2O3 % | ≤0.9 | ≤0.8 | ≤0.6 | ≤0.4 | ≤0.3 | ≤0.1 | |

| The remaining components can be determined through negotiation between the supplier and the buyer when necessary. | |||||||

| water absorption,% | 3±1,It can also be determined by negotiation between the supplier and the buyer | ||||||

| proportion,kg/m³ | 2.5-3.0 | 2.7-3.2 | 2.9-3.2 | ≥3.1 | ≥3.2 | ≥3.4 | |

| Bulk density,kg/m³ | 1400-1550 | 1400-1650 | 1500-1800 | 1700-1950 | 1800-1950 | ≥1900 | |

| Dust, crack or break | A single bag is less than 5% | ||||||

| Size deviation | Uniform sphere, the ratio of the largest to smallest diameter of a ceramic sphere does not exceed 1.2 | ||||||

| Dimensional tolerance | ≤10mm | ±1.0 | |||||

| 11—25mm | ±1.5 | ||||||

| 26—50mm | ±2.0 | ||||||

| ≥50mm | ±3.0 | ||||||

| Free fall strength | Lossless rate ≥99% | ||||||

| Compressive strength | φ3 | ≥250 | ≥300 | ≥350 | ≥400 | ≥500 | ≥500 |

| φ6 | ≥800 | ≥1000 | ≥1000 | ≥1200 | ≥1500 | ≥1500 | |

| φ8 | ≥1500 | ≥1600 | ≥1800 | ≥2000 | ≥2500 | ≥2500 | |

| φ10 | ≥2000 | ≥2500 | ≥2800 | ≥3000 | ≥3500 | ≥3500 | |

| φ13 | ≥3000 | ≥3000 | ≥3500 | ≥4000 | ≥5000 | ≥5000 | |

| φ16 | ≥3500 | ≥4000 | ≥4500 | ≥5000 | ≥6000 | ≥7000 | |

| φ20 | ≥6000 | ≥6000 | ≥7000 | ≥8000 | ≥10000 | ≥12000 | |

| φ25 | ≥7000 | ≥7000 | ≥8000 | ≥10000 | ≥15000 | ≥17000 | |

| φ30 | ≥8000 | ≥9000 | ≥10000 | ≥12000 | ≥17000 | ≥19000 | |

| φ38 | ≥10000 | ≥12000 | ≥13000 | ≥15000 | ≥20000 | ≥22000 | |

| φ50 | ≥12000 | ≥14000 | ≥16000 | ≥18000 | ≥22000 | ≥26000 | |

| φ75 | ≥16000 | ≥18000 | ≥20000 | ≥22000 | ≥25000 | ≥30000 | |

| 50-75 | 55-75 | 60-80 | ≥80 | ≥82 | ≥85 | ||

| Wear rate % | ≤2 | ≤1 | |||||

| acid solubility,% | ≤6 | ||||||

| Alkalinity,% | ≥77 | ≥85 | ≥90 | ≥92 | ≥95 | ≥97 | |

| Refractoriness,℃ | ≥400 | ≥500 | ≥700 | ≥1000 | ≥1000 | ≥1000 | |

| Resistant to sudden pressure difference | Non-destructive rate ≥ 99%, no change in compressive strength and pressure after sudden change is less than 25% | ||||||

| Resistant to sudden temperature changes | Lossless rate≥99% | ||||||

| Package | Iron drum packaging | Packed in iron drums, sealed with thick PP or PE plastic bags | |||||

| Woven bag packaging | Available in sturdy and UV-resistant woven bags | ||||||

| Note: Bulk density data is for reference only, not as a basis for acceptance. | |||||||

| 99 Filling Ball Water Absorption | ||

| 99 filler | diameter | diameter |

| roll forming | φ<25mm | <5% |

| Machine press forming | φ>25mm | <10% |

| Al2O3 | ≥99% |

| SiO2 | ≤0.14% |

| Fe2O3 | ≤0.04% |

| CaO +MgO | ≤0.03% |

| TiO2 | ≤0.06% |

| Na2O | ≤0.1% |

| K2O | ≤0.1% |

| CONDITION | INDEX |

| load softening (yb/t370-1995) | Deformation under 0.2mpa pressure is less than 0.6% |

| Thermal shock resistance (yb/t376.2-1995) | 1200°C down to 600°C. 10 times without surface cracks |

| Reburn line changes (gb/t3997.1-1998) | 1400 ℃ for 12 hours, the maximum value is 0.25%, the average value is less than 0.20% |

| Bulk density (gb/t2997-2000) | 3.2-3.50 g/cm3 |

| crushing strength | Meet more than 230 kg/cm2 |

| Apparent porosity | 12-18% |

| Bulk density | 2.1-2.3g/cm3 |